Guideway material reduces cost of large-volume gantry CMMs

In the world of aerospace manufacturing, the accuracy and precision of machinery is critical. Coordinate measuring machines (CMMs) play a crucial role in this industry, allowing manufacturers to ensure that their parts meet strict tolerances and perform properly. However, the cost of large-volume gantry CMMs has traditionally been a barrier to many companies looking to invest in this technology. That's where lightweight guideway technology comes in.

LK Metrology has introduced a new series of large-capacity CMMs that use lightweight guideway technology. These machines are designed to offer the high accuracy of ceramic moving guideway technology but at a lower cost. This makes them a more accessible option for companies that require the precision of gantry CMMs but don't have the budget for the higher-end models.

What is Lightweight Guideway Technology?

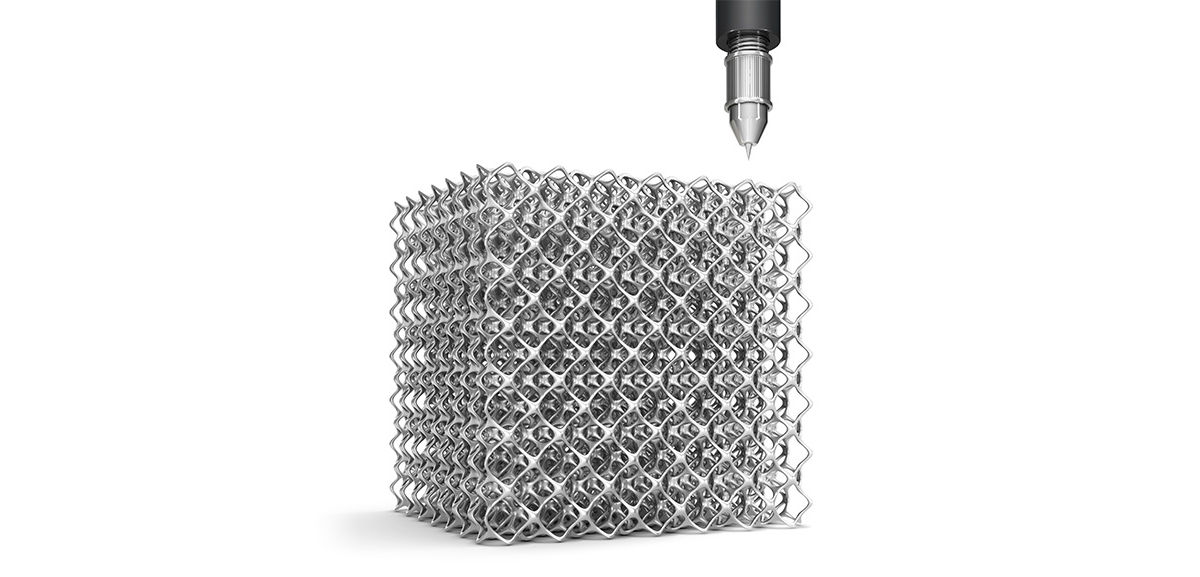

Lightweight guideway technology is a relatively new development in the world of CMMs. It uses carbon fiber-reinforced polymer (CFRP) as the material for the guideways, which are the rails that the CMM's probing system moves along. This material is much lighter than traditional materials like steel or granite, which makes it easier to move and reduces the amount of energy required for acceleration and deceleration.

The benefits of lightweight guideway technology go beyond just cost savings. Because the guideways are lighter, they are also more responsive to changes in temperature and humidity. Traditional guideway materials can expand and contract with changes in the environment, which can cause accuracy issues. CFRP, on the other hand, has a very low coefficient of thermal expansion, making it more stable and reliable.

How Does Lightweight Guideway Technology Reduce Costs?

The use of CFRP for guideways has a significant impact on the overall cost of a CMM. Because the material is lighter, it requires less energy to move, which means that the motors and other components can be smaller and less expensive. Additionally, CFRP is easier to machine than traditional materials like granite, which reduces manufacturing costs.

Another cost-saving benefit of lightweight guideway technology is that it allows for larger machines without a proportional increase in cost. Traditional guideway materials can be prohibitively expensive for machines with larger travel ranges, which means that many manufacturers opt for smaller machines. With CFRP guideways, larger machines become more feasible and accessible.

Applications for Large-Volume Gantry CMMs

Large-volume gantry CMMs are used in a variety of applications in the aerospace industry. They are frequently used to inspect large parts like aircraft wings, fuselages, and engines. The precision and accuracy of these machines are critical for ensuring that these parts are safe and reliable.

The use of lightweight guideway technology in large-volume gantry CMMs makes these machines more accessible to manufacturers in the aerospace industry. The lower cost of the machines means that more companies will be able to invest in this technology, which will ultimately lead to safer and more reliable parts.

In Conclusion

The introduction of lightweight guideway technology is a significant development in the world of coordinate measuring machines. It allows for the high accuracy of ceramic moving guideway technology at a lower cost, making large-volume gantry CMMs more accessible to manufacturers. In the aerospace industry, this technology is critical for ensuring the safety and reliability of large parts. As this technology continues to evolve and improve, it will undoubtedly have a significant impact on the industry.