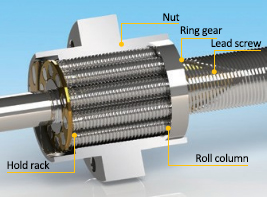

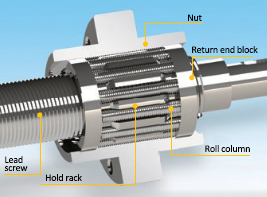

The difference in structure determines that the two have different application fields. The planetary roller screw pair is mainly used in the dry and heavy load field, while the circulating roller screw is biased towards precision equipment. Planetary roller screws have high bearing capacity and high reliability, and are mainly used in: ● Press machine tools ● Injection molding ● Military equipment ● Iron and steel industry ● nuclear industry Circulating roller screws with high lead resolution, coupled with its high load carrying capacity and high reliability, it is mainly used in: ● Precision instruments ● Precision grinders ● Aerospace ● Medical equipmentCirculating Roller Screws with centrally located nut flange and no axial preload.Series ListHighest efficiency rolling motion (even in shallow lead designs). Multiple contact points that carry large loads with very high resolution. Small axial movement (even with very shallow leads).Series ListHigh rotational speeds with faster acceleration (no adverse effects). The most reliable screw solution available. Higher cost option with highest performance.Series ListMaximum backlash of single nuts: 0.03mm (can be less on request). Nuts with lubrication holes available if required.Series ListAn inverted roller screw works on same principle as a planetary roller screw. In order to reduce the overall actuator dimensions, either the nut or screw can be directly used as a push tube. An inverted roller screw has a high speed capability similar to a planetary roller screw, but the load acts directly on the translating push tube.Series List

The difference in structure determines that the two have different application fields. The planetary roller screw pair is mainly used in the dry and heavy load field, while the circulating roller screw is biased towards precision equipment. Planetary roller screws have high bearing capacity and high reliability, and are mainly used in: ● Press machine tools ● Injection molding ● Military equipment ● Iron and steel industry ● nuclear industry Circulating roller screws with high lead resolution, coupled with its high load carrying capacity and high reliability, it is mainly used in: ● Precision instruments ● Precision grinders ● Aerospace ● Medical equipmentCirculating Roller Screws with centrally located nut flange and no axial preload.Series ListHighest efficiency rolling motion (even in shallow lead designs). Multiple contact points that carry large loads with very high resolution. Small axial movement (even with very shallow leads).Series ListHigh rotational speeds with faster acceleration (no adverse effects). The most reliable screw solution available. Higher cost option with highest performance.Series ListMaximum backlash of single nuts: 0.03mm (can be less on request). Nuts with lubrication holes available if required.Series ListAn inverted roller screw works on same principle as a planetary roller screw. In order to reduce the overall actuator dimensions, either the nut or screw can be directly used as a push tube. An inverted roller screw has a high speed capability similar to a planetary roller screw, but the load acts directly on the translating push tube.Series List